Introduction

The global pet food industry is projected to exceed a staggering $280 billion by 2025, fueled by the growing popularity of pet ownership and increasing consumer demand for premium and innovative pet food products. To meet this demand, manufacturers are embracing groundbreaking technologies and innovative production processes, transforming the pet food landscape.

Technological Advancements

1. Precision Nutrition

Feeding pets a balanced, nutrient-rich diet is paramount for their health and well-being. Advanced nutrition technologies, such as pet-specific food analysis and tailored dietary recommendations, enable manufacturers to develop personalized pet food solutions that address the unique nutritional needs of individual animals. This precision approach ensures optimal health outcomes and enhances the overall quality of pet life.

2. Extrusion Revolution

Extrusion technology has become a cornerstone of pet food production. By combining heat, moisture, and pressure, extruders create kibble with specific shapes, textures, and density. However, advancements in extrusion technology have unlocked new possibilities. High-shear extrusion, for instance, enhances nutrient bioavailability, while texturization offers innovative and appealing textures for pets to savor.

3. Novel Ingredients

The search for novel and sustainable ingredients is at the forefront of pet food innovation. Plant-based proteins, insect proteins, and alternative raw materials are being explored to address growing consumer concerns about sustainability and ethical sourcing. By leveraging these ingredients, manufacturers can reduce their environmental footprint while meeting the dietary requirements of pets.

4. AI and Automation

Artificial intelligence (AI) and advanced automation are transforming every aspect of pet food manufacturing. AI-driven quality control systems monitor production processes, ensuring consistency and safety. Automated equipment, such as robotic palletizers and packaging systems, reduce labor costs, increase efficiency, and minimize human error.

Production Innovations

1. Smart Manufacturing

Embracing the principles of Industry 4.0, pet food manufacturers are adopting smart manufacturing practices. These practices encompass the integration of sensors, real-time data analytics, and cloud connectivity. By harnessing the power of data, manufacturers can optimize production processes, reduce waste, and enhance transparency for consumers.

2. Sustainable Production

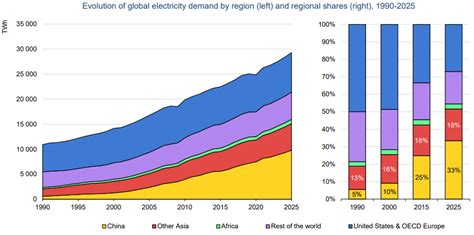

Sustainability is a key consideration in pet food production. Manufacturers are implementing eco-friendly measures, such as reducing water consumption, utilizing renewable energy sources, and adopting sustainable packaging solutions. These initiatives not only benefit the environment but also align with the increasing demand for ethical and responsible products among consumers.

3. Localized Production

To meet the growing demand for locally sourced and fresher pet food, manufacturers are establishing localized production facilities. These facilities enable faster delivery, reduced transportation emissions, and better responsiveness to regional market needs.

4. Customer-Driven Innovation

Consumer feedback is a crucial driver of pet food innovation. Manufacturers are leveraging market research, online reviews, and social media platforms to gather insights into pet owners’ preferences and concerns. This customer-centric approach fosters transparency, builds brand loyalty, and ensures that products meet evolving market demands.

Case Studies

1. Example 1: Automated Pet Food Control

A pet food manufacturer implemented a fully automated production line, integrating sensors, robots, and AI systems to monitor and control every step of the process. This innovation resulted in a 35% reduction in production time, improved product quality, and a 20% decrease in labor costs.

2. Example 2: Sustainable Packaging Solutions

Another manufacturer invested in biodegradable and recyclable packaging materials for their pet food products. This eco-friendly solution reduced the company’s carbon footprint by 15% and enhanced its reputation as a responsible brand.

Future Outlook

The pet food industry is poised for continued growth and innovation in the years to come. As consumer expectations evolve and technological advancements emerge, manufacturers will need to:

- Continue investing in precision nutrition and novel ingredients

- Embrace smart manufacturing and automation to optimize production processes

- Prioritize sustainability and ethical sourcing

- Actively engage with consumers to drive innovation and build loyalty

Conclusion

Pet food manufacturing and production innovation is a dynamic and rapidly evolving landscape. By embracing cutting-edge technologies and innovative production methods, manufacturers can meet the growing demand for premium and nutritious pet food products while promoting sustainability and consumer satisfaction. As the industry continues to innovate, the future holds exciting possibilities for ensuring the health, well-being, and enjoyment of our beloved pets.

Table 1: Key Market Statistics

| Statistic | Value |

|---|---|

| Global Pet Food Market (2023) | $215 billion |

| Projected Growth by 2025 | 15% |

| Share of Pet Food in Global Food and Beverage Market | 2% |

Table 2: Pet Food Manufacturing Innovations

| Innovation | Description |

|---|---|

| Precision Nutrition | Tailored dietary recommendations based on individual pet needs |

| Extrusion Revolution | High-shear extrusion and texturization for enhanced nutrient bioavailability and appealing textures |

| Novel Ingredients | Exploration of plant-based proteins, insect proteins, and alternative raw materials |

| AI and Automation | Use of AI for quality control and automation for increased efficiency |

Table 3: Production Innovations

| Innovation | Description |

|---|---|

| Smart Manufacturing | Integration of sensors, data analytics, and cloud connectivity |

| Sustainable Production | Eco-friendly measures such as reduced water consumption and renewable energy |

| Localized Production | Establishing production facilities closer to regional markets |

| Customer-Driven Innovation | Leverage of consumer feedback to guide product development |

Table 4: Case Study Summary

| Case Study | Innovation | Results |

|---|---|---|

| Example 1 | Automated Pet Food Control | 35% reduction in production time, 20% decrease in labor costs |

| Example 2 | Sustainable Packaging Solutions | 15% reduction in carbon footprint, enhanced brand reputation |