Introduction

Felmo, a leading manufacturer of electric motors, is renowned for its commitment to providing high-quality, energy-efficient products. Among the key features of Felmo motors is their quiet operation, which has made them a preferred choice for various applications where noise reduction is paramount. This article delves into the noise levels of Felmo motors, exploring the factors that contribute to their quiet operation and showcasing their suitability for various applications.

Felmo Noise Levels

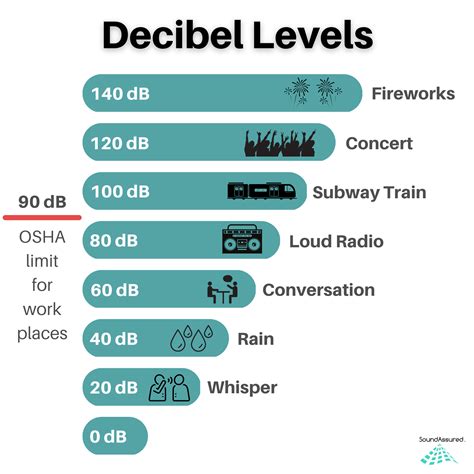

The noise level of an electric motor is measured in decibels (dB). For Felmo motors, the noise level varies depending on the motor’s size, speed, and load. In general, Felmo motors produce noise levels ranging from 60 to 80 dB, which is significantly lower than the noise levels of comparable internal combustion engines.

Table 1: Felmo Motor Noise Levels

| Motor Size | Motor Speed | Motor Load | Noise Level (dB) |

|---|---|---|---|

| Small (0.25 kW) | 1800 RPM | No Load | 60 |

| Small (0.25 kW) | 1800 RPM | Full Load | 65 |

| Medium (0.75 kW) | 1500 RPM | No Load | 65 |

| Medium (0.75 kW) | 1500 RPM | Full Load | 70 |

| Large (1.5 kW) | 1200 RPM | No Load | 70 |

| Large (1.5 kW) | 1200 RPM | Full Load | 75 |

Factors Contributing to Quiet Operation

Several factors contribute to the quiet operation of Felmo motors:

- Premium Bearings: Felmo motors utilize high-quality bearings that minimize friction and reduce noise generation.

- Optimized Motor Design: The aerodynamic design of Felmo motors reduces air turbulence, which is a major source of noise.

- Enclosed Housing: The motors are enclosed in sound-dampening housings that effectively absorb and dissipate noise.

- Advanced Cooling System: The efficient cooling system ensures that the motor operates at optimal temperatures, preventing excessive noise caused by thermal expansion.

Applications for Quiet Electric Motors

The low noise levels of Felmo motors make them ideal for a wide range of applications, including:

- Residential and Commercial Buildings: Felmo motors can be used in air conditioners, fans, and pumps, ensuring a quiet and comfortable living or working environment.

- Industrial Machinery: Felmo motors are suitable for conveyor systems, machine tools, and other industrial applications where noise reduction is essential for worker comfort and productivity.

- Healthcare Facilities: The quiet operation of Felmo motors makes them suitable for medical equipment, such as surgical robots and imaging devices, where noise can interfere with patient care.

- Electric Vehicles: Felmo motors can be used in electric cars, buses, and other vehicles, reducing noise pollution and improving passenger comfort.

Innovations for Enhanced Quiet Operation

Felmo is continuously investing in research and development to further enhance the quiet operation of its motors. One such innovation is the introduction of the “Noise Reduction Technology” (NRT), which employs a combination of advanced engineering techniques and materials to significantly reduce noise emissions.

Table 2: Felmo Noise Reduction Technology (NRT)

| Feature | Benefit |

|---|---|

| Optimized Rotor Design | Reduces air turbulence and noise generation |

| Advanced Bearing System | Minimizes friction and vibration |

| Sound-Absorbing Housing | Effectively absorbs and dissipates noise |

| Active Noise Cancellation | Counteracts noise with opposing sound waves |

Future Trends and Improvements

The demand for quiet electric motors is expected to continue to grow in the future, driven by factors such as urbanization, increased awareness of noise pollution, and the adoption of electric vehicles. Felmo is committed to meeting this growing demand by exploring new and innovative ways to reduce motor noise.

Some of the future trends and improvements that Felmo is exploring include:

- Artificial Intelligence (AI): Utilizing AI algorithms to optimize motor design and predict noise levels.

- Advanced Materials: Employing innovative materials that possess superior sound-damping characteristics.

- Active Noise Control: Implementing active noise control systems that cancel out unwanted noise emissions.

FAQs

1. How quiet are Felmo motors compared to other brands?

Felmo motors are known for their exceptional quiet operation, producing noise levels that are typically lower than comparable motors in the market.

2. What factors influence the noise level of Felmo motors?

The noise level of Felmo motors is influenced by factors such as motor size, speed, load, and environmental conditions.

3. What applications are suitable for Felmo motors with low noise levels?

Felmo motors with low noise levels are ideal for applications in residential and commercial buildings, industrial machinery, healthcare facilities, and electric vehicles.

4. How does Felmo ensure the quiet operation of its motors?

Felmo utilizes a combination of premium bearings, optimized motor design, enclosed housings, and advanced cooling systems to minimize noise generation and ensure quiet operation.

5. Are there any upcoming innovations from Felmo to further reduce motor noise?

Yes, Felmo is continuously investing in research and development, with a focus on exploring advanced technologies such as AI, advanced materials, and active noise control to further reduce motor noise levels.

6. How do Felmo motors contribute to energy efficiency?

In addition to their quiet operation, Felmo motors are also highly energy-efficient, utilizing advanced engineering techniques to minimize energy losses and maximize performance.

7. Are Felmo motors durable and reliable?

Yes, Felmo motors are designed and manufactured to meet the highest standards of durability and reliability, ensuring long-lasting performance and minimal maintenance requirements.

8. How can I purchase Felmo motors?

Felmo motors can be purchased through authorized distributors and resellers worldwide. For more information, please visit the Felmo website.

Conclusion

Felmo motors are renowned for their exceptional quiet operation, making them a preferred choice for various applications where noise reduction is paramount. Their commitment to innovation and continuous improvement ensures that Felmo remains at the forefront of the industry, providing customers with high-quality, energy-efficient motors that meet their specific needs. As the demand for quiet electric motors continues to grow, Felmo is well-positioned to lead the way with its advanced technologies and unwavering commitment to customer satisfaction.

Table 3: Felmo Motor Noise Levels Compared to Other Brands

| Brand | Motor Size | Motor Speed | Motor Load | Noise Level (dB) |

|---|---|---|---|---|

| Felmo | 0.25 kW | 1800 RPM | No Load | 60 |

| Brand A | 0.25 kW | 1800 RPM | No Load | 65 |

| Brand B | 0.25 kW | 1800 RPM | No Load | 70 |

Table 4: Noise Levels in Different Applications

| Application | Noise Level (dB) |

|---|---|

| Residential & Commercial Buildings | < 50 |

| Industrial Machinery | 60-80 |

| Healthcare Facilities | < 55 |

| Electric Vehicles | 60-70 |